Case study on use of motors and motor controllers

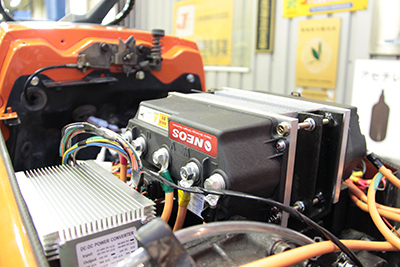

Products adopted: AC motor IA180

/NEOS controller M type

The compact, high-output motor and output adjustment tool has enabled EV Japan to develop vehicles in many different fields.

EV Japan Inc.

Mr. Chotaro Nishida , Representative Director

Introduction

EV Japan Inc. was established by a volunteer consortium of automobile repair plants in the Kansai region with the goal of revitalizing local communities and contributing to the environment. The company develops electric vehicles for a variety of uses, from custom-made tourism vehicles used at tourist sites to modified electric tractors.

Mr. Nishida, representative of EV Japan, explains why the company chose Toyota Industries motors and motor controllers and the benefits they've brought to his business.

Reason for selection

For us, it was essential that Toyota Industries' compact, high-output motors and motor controllers had been used for the efficient development of many kinds of vehicles.

We develop a broad range of electric vehicles, and motors and motor controllers are core components of all our vehicles. Most importantly, we need compact, high-output motors and motor controllers, with a good balance between superior mountability and driving power. With these features, the same components can be used even in vehicles with significantly different mounting and drive requirements. Toyota Industries' proposal matched our product specifications exactly.

Learning from past mistakes to gain a sense of security on quality.

In the past, we used components from manufacturers outside Japan and we experienced problems with quality. For that reason, we prioritized quality, including the quality of the supplier structure. We knew that Toyota Industries motors and motor controllers had a great track record in lift trucks. This gave us a very strong sense of security in choosing them to ensure quality.

The motor controller's vehicle adaptation tool was easy to understand and use, making the vehicle development process very smooth.

Once we started using the Toyota Industries NEOS controller, I found the vehicle adaptation tool to be a great advantage. It made it easy to see inside the controller to check the parameter settings and the operational status. Other manufacturers offered this type of software, but the Toyota Industries' tool was by far the easiest to use. One of the challenges we face as a company is how to develop electric vehicles for a wide range of customers, from Electric bus to Agricultural machinery. Their vehicles have different requirements for handling and power output. Given that, Toyota Industries were very appealing for their intuitive feeling of the user interface and ease of use.

Results

Our customers are very satisfied, and in this way we are realizing our mission of revitalizing local communities and contributing to the environment.

Our electric vehicles are being used at Karuizawa Prince Hotel, Sano City's Michi no Eki Domannaka Tanuma tourist spot. Our customers are very happy with the smooth, quiet ride. We are also involved in a small-scale hydroelectric project in Yakuno City to generate renewable power. Here, we are helping local farmers convert their gas engine tractors into electric tractors. Toyota Industries motors and motor controllers have made it possible for us to realize our mission of revitalizing local communities and contributing to the environment. And we've just begun. We have great things ahead of us.

EV Japan Inc. 1-10-32 Kozushima, Toyonaka City, 561-0843 Osaka Prefecture